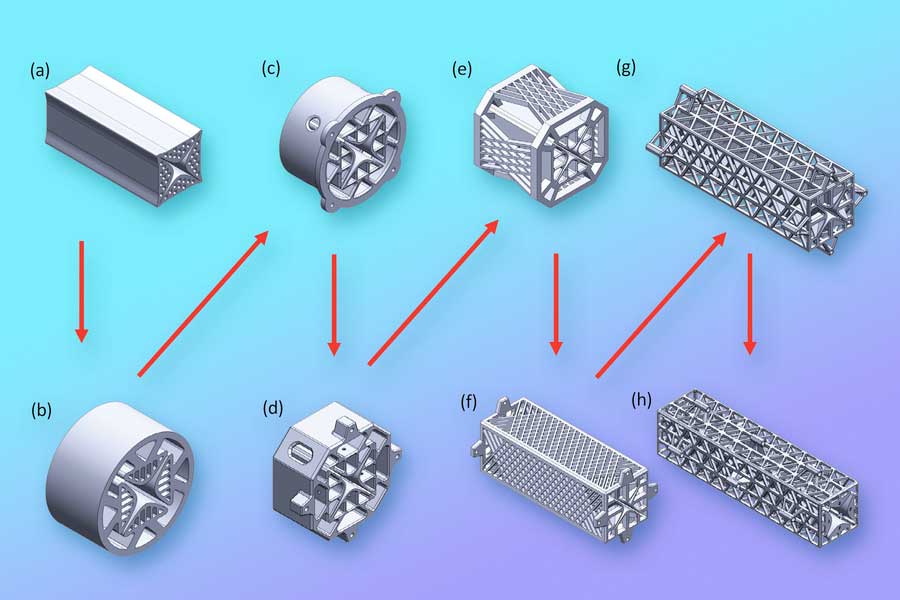

Massachusetts Institute of Technology (MIT) scientists have used 3D printing to create key components for portable mass spectrometers. Like MIT in one Press release Writes, This is a quadrupole mass filter. It can be manufactured more easily and cheaply than conventional mass filters.

Mass spectrometers are used for chemical analysis of substances. They are used in criminology, medicine or geography. However, the devices are generally bulky, expensive and sensitive. This severely limits their use in remote areas.

High precision printing made of glass ceramic plastic

Researchers led by Luis Fernando Velázquez-Garcia from MIT have now succeeded in creating a quadrupole mass filter using 3D printing. It is as accurate as some commercially available mass filters that cost more than US$100,000, but is much cheaper and faster to manufacture.

According to MIT, a glass-ceramic-based plastic that can withstand high temperatures is used. Components can be manufactured in one piece using a VAT photopolymerization 3D printer. So it doesn't have to be installed separately, which reduces the sources of error.

Lightweight and modularly expandable

The plastic mass filter is only a quarter as thick as comparable stainless steel versions. In tests with a commercial mass spectrometer, the 3D printed components achieved higher resolution than other compact filters.

According to Velásquez-García, this is an important step towards a fully 3D printed, compact mass spectrometer. It can, for example, analyze materials on site in remote areas without sending samples. Additional components such as ion sources can be added in a modular manner.

Don't miss out on more news!

We deliver the most important 3D printing news and information to your inbox every week for free. Sign in here. We are too LinkedIn to find out. You can do it, we can Follow along here!